To ensure consistent, high-quality production results, constant measurements and checks during processing are indispensable. Since taking samples and evaluating them in the laboratory is laborious, time-consuming and provides only spot checks with a time delay, inline measurement is particularly important precisely in these production areas: the processes can be checked at any time and adjusted if necessary. This is why IPC Process-Center GmbH & Co. KG, a Glatt-group company manufacturing innovative granules and pellets for the pharmaceutical and food industries, uses Parsum GmbH inline particle probes for continuously monitoring their sensitive processes. The measuring accuracy of the IPP 70‑S and IPP 70-Se probes means that the particle-size distributions of intermediate and end products are constantly monitored, so that flexibly adjusted and optimised processes can be controlled precisely and reproducible quality can be guaranteed. Optimal process management and the avoidance of production errors and entire off-spec batches mean that considerable financial savings can be achieved.

“The installation of the two new inline probes gives us the advantage that the manufacturing process can be monitored continuously and thus process safety is greatly improved,” explains Jan Demian, the production-planning engineer responsible for measurement technology and data evaluation at IPC Process-Center GmbH & Co. KG. “Furthermore, the workload for sampling and analysis is much lower than with previous process monitoring using screen analysis, and the uninterrupted data can be evaluated and assessed right up to the end of the campaign.” However, precise measurement values are also essential during the difficult pre-production phase in order to carry out fine adjustment of all the parameters and to start the process correctly.

Parsum measurement technology was installed in a Glatt 250 (GFG 250) fluidised-bed granulator, which can be converted into a ProCell spouted bed by adding a further processing unit.

The process chamber of the GFG 250 is approximately 3.5 m long, 0.8 m wide and 0.7 m high. The hold-up is between 200 and 700 kg, depending on the product and method.

The process chamber of the GFG 250 is approximately 3.5 m long, 0.8 m wide and 0.7 m high. “The desired charge quantity, what we call the ‘hold-up’, depends on the product and the process and is between 200 and 700 kg,” says Demian. IPC uses this completely continuously operating system mainly for the spray granulation of liquids and the agglomeration of powders. For the latter case, the starting material is fed continuously into the process chamber and a binder solution is sprayed through dual-fluid nozzles situated in the floor. “The aim is to bring together individual particles of starting material using the adhesive properties of the binder to form larger agglomerations until the desired particle-size distribution is reached,” explains Demian.

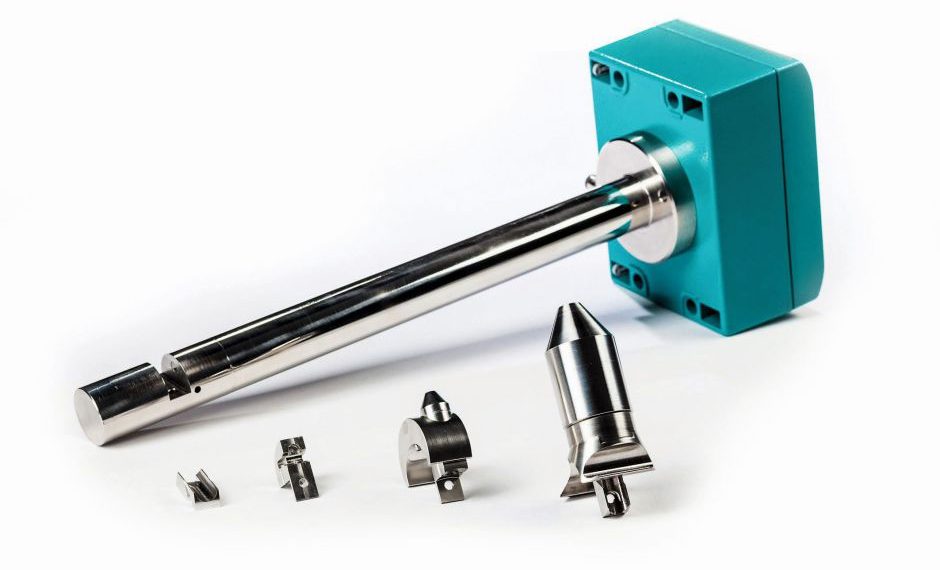

Installation of the IPP 70-Se and IPP 70‑S probes

The probes can be used to monitor the growth in particle size in real time. The ATEX-certified IPP 70-Se probe has been installed directly in the process chamber for in-process checks and tracks the course of the process by constantly monitoring the granulation.

Fluidised-bed and other processes can be developed and improved more quickly using process-analytical technology (PAT). For instance, direct measurement in the fluidised bed makes it possible to adjust the appropriate parameters where needed to optimise the process and fully exploit the potential

of the production plant. In this way, the amount of material circulating in the adjoining screening and grinding circuit can also be considerably reduced.

The IPP 70‑S is used to monitor the target fraction downstream of the classifying screen and is situated directly behind the classifier at the outlet. The ATEX-certified IPP 70-Se has been installed directly in the process chamber for in-process checks and tracks the course of the process by constantly measuring the particle-size distribution.

Source: Parsum Gesellschaft für Partikel‑, Strömungs- und Umweltmesstechnik mbH

The second probe, of the IPP 70‑S type, is used to monitor the target fraction downstream of the classifying screen and is situated directly behind the classifier at the product outlet. At this measurement point, the particle-size distribution of the specified product is checked and immediately approved if all requirements are met. Malfunctions of the classifier or a broken screen can be detected here straight away, so the personnel responsible can take suitable steps quickly and accurately. “If the probe is used inline, the measurement results are available immediately and the continuous display of the particle-size curve shows how the process is currently running,” says Stefan Dietrich, Parsum’s managing director. “For the operator, the measurement forms a sort of window allowing a direct insight into the process.” Normally, the batch is checked by means of multiple spot checks during the process. Measurement at the outlet, and the associated parametric approval in particular, constitutes a completely new approach for the pharmaceutical industry.

Upgrading to the new D24 disperser

In addition to the probes, IPC also uses a newly developed

D24 disperser, with which the service time between the necessary cleaning operations was radically improved. The inline disperser ensures that the

particles are isolated for measurement even under the difficult conditions in the fluidised bed. Even moist or sticky materials and substances with high proportions of fines can be measured reliably, which would not be possible without dispersion. “With the previous model, the D23, product constituents would accumulate on the disperser after a while when measuring directly in the fluidised bed. Since the probe is not accessible for cleaning during operation, it was not possible to continue measuring the particle size without interrupting the process,” explains Demian. Changing to the new D24 rectified these problems, and process times of up to two weeks without cleaning and with continuous data recording by the IPP 70-Se probe could be achieved.

Special technology from Parsum was installed in a Glatt 250 (GFG 250) fluidised-bed granulator, which can be converted into a ProCell spouted bed by adding a further processing unit. IPC uses this completely continuously operating system mainly for the spray granulation of liquids and the agglomeration of powders.

Source: IPC Process-Center GmbH & Co. KG

IPC is very happy with the use of the Parsum probes: “The continuous checking and monitoring of particle size during the process allows us to adjust the process parameters according to the desired target specification so as to achieve an optimal result,” says Demian. “By monitoring the target fraction, we can detect deviations from the desired result early and react quickly to protect the process.”

Current project: Implementation of Parsum View 3.0 software

A current project aim to put GMP’s Parsum View 3.0 software, which makes measurement data centrally accessible, into operation at the Dresden company. This software provides very user-friendly management of formulations, batches and users, and an audit trail that records all operator interactions. In the process, the program stores data directly in an SQL database. The data is therefore tamperproof and satisfies the guidelines of the American Food and Drug Administration (FDA). “Although we use the system locally, it can be accessed from any authorised workstation via a network,” says Demian confidently. The Parsum-View add-on has been developed specifically for the pharmaceutical sector, meets the highest security demands and complies with the requirements of 21 CFR 11.

IPC has signed a maintenance contract with Parsum, which means that the company can also benefit from an inspection of the measurement probes with the annual Operational Qualification, ensuring high system availability.