The operating conditions on site influence the condition and functionality of equipment in process plants in many ways. In addition to the deposits or contamination generated in the process, accessibility and installation space are important criteria in ease of maintenance. The solution to this problem is a new generation of control devices. Instead of external attachments, they have an integrated air guide as a perfect fit for the actubar® pneumatic rotary actuators, which have a pneumatic interface in the top of the actuator. Plant construction and operation are significantly less susceptible to faults as there is no need for any external piping or tubing. Furthermore, thanks to special air guide plates, these advantages can also be used for positioners from other well-known manufacturers. Based on the same system and equipped with the same advantages, decentralized controls with integrated pressure measurement have also been developed: a control for valves with inflatable seal and a control of actuators that ensure safe and energy-efficient operation between air generators and compressed air networks.

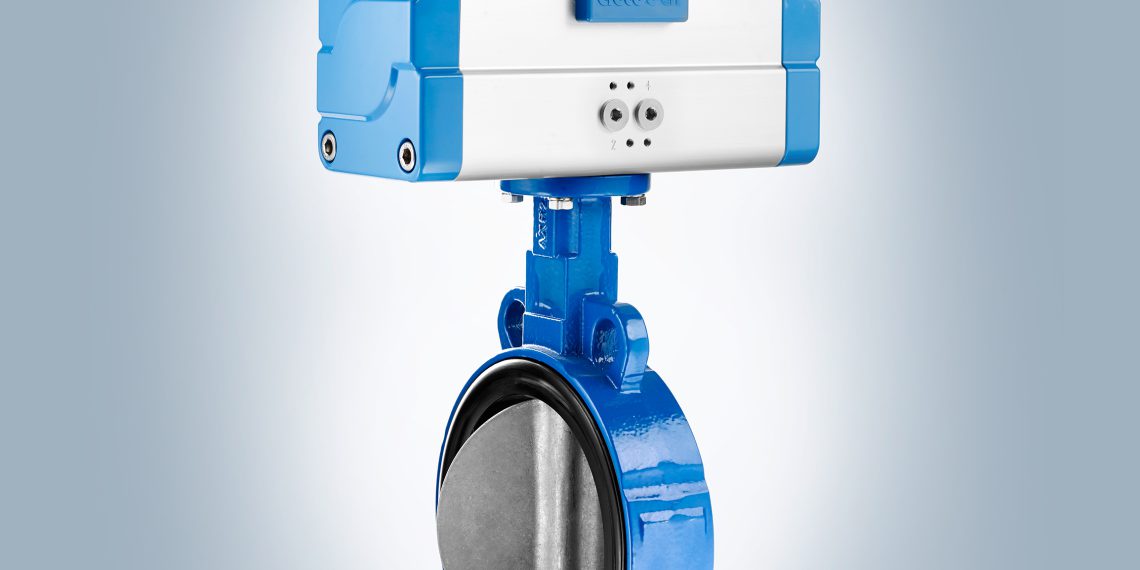

INTEGRATED AIR GUIDANCE ENABLES DIRECT MOUNTING OF CONTROL DEVICES ON PNEUMATIC ROTARY ACTUATORS

Pneumatic rotary actuators have long been used to automate rotary valves in industry. However, in addition to the actuator, further components such as pilot valves, positioners or end position feedback signals are required to control and regulate valves. Until now, these components have been connected to the actuator via standardized interfaces. However, the connection of the components to the pneumatic rotary actuator, which consists of a mounting bridge as well as electrical and pneumatic control and supply lines, still represents a considerable effort. This results in cable loops and overall complex piping or tubing that must be individually adapted to each actuator. The structure always results in several sealing points and thus weak points in the automation solution.

Also, the known interfaces according to VDI/VDE 3845, Part 1, require a certain amount of installation space, which has to be taken into

must be taken into account in the plant. In addition, accessibility to the actuator must be guaranteed from at least two sides.

from at least two sides. bar GmbH has recognized the need to integrate and reduce interfaces and offers corresponding solutions with the bar-vacotrol system family.

With the patented actuator series actubar® the prerequisites for the direct mounting of components for position feedback, position control by means of positioner and further decentralized

control systems. The key to this is the additional pneumatic interface on the top of the actuator. This puts pneumatics and position sensing on the same level (Fig. 1). The new generation of control components developed to match this (Table 1) can operate both interfaces simultaneously in one device. The advantages of integrated air guidance at a glance compared to external

piping or tubing:

- compact design

- fewer components

- accessibility from only one mounting level, the top of the actuator required

- considerable reduction of assembly times

- Lines or cables as trip hazards, dirt and dust traps are eliminated

- problem-free change or exchange since no piping has to be adapted

- modular system

- Reliable and reusable seal similar to the Namur interface for solenoid valves

- Minimization of sealing points down to only one

- short distances and reduction of dead volume in the pipelines

- Vibration insensitivity Integrated pressure measurement possible

COMBINATIONS WITH COMMERCIALLY AVAILABLE CONTROLLERS VIA AIR GUIDE PLATES

In some industries, positioners from certain manufacturers are mandatory. These are

These are long established branded products suitable for automation by means of rotary and linear actuators.

linear actuators. In order to extend the range of application and to make the previously described advantages of the bar-vacotrol system also usable in connection with these positioners suitable for hazardous areas, a new adaptation system has been developed. It consists of flat air guide plates with which these positioners can also be connected to the actubar pneumatic rotary actuator without the need for piping or hoses. The modular combination possibilities of the bar-vacotrol system are also implemented for third-party devices with this solution.

SPECIAL CONTROL FOR COMPRESSED AIR NETWORKS AND COMPRESSED AIR TREATMENT SYSTEMS

In most plants, the interface between a compressor station and the downstream compressed air network is an automatic valve. This serves to disconnect the compressed air network as soon as, for example, on the consumers are not in operation, for example, at the weekend. The pressure condition in the network after separation from the compressor station is usually not definable, since leakages occur again and again in a widely branched compressed air network. Often, the network is then completely vented. If the automatic valve is then opened to connect the network, very high flow velocities can occur in the network. This leads to an overload of the compressed air system. In this case, the refrigeration dryers are driven beyond their capacity limit and can be destroyed. In addition, uncontrollable amounts of condensed water enter the compressed air network. Until now, the problem has been solved by slowing down the automatic valve via a heavily throttled pneumatic rotary actuator. This method avoided the sudden switching on of the network. However, in a large compressed air network, such a delay is often not sufficient in the overall capacity. Also, during normal operation, when the network is not vented, the appropriately selected and adjusted valve also opens slowly, which is neither desired nor necessary in this case. For this application, the bar-PCS control unit (Fig. 3 ) was also newly developed for direct mounting. The considerable advantage over the standard is that bar-PCS can be operated depending on the prevailing pressure conditions.

The electro-pneumatic control unit coordinates the functional sequence of the OPEN and CLOSED movements of the shut-off valve depending on the pressure conditions.

shut-off valve as a function of the feed pressure of the compressed air preparation system into the compressed air network. By means of a digital pressure switch with freely programmable parameters, the system is optimally adapted to the respective plant. Both the pressure range and the hysteresis of the pressure switch are freely selectable and can be read via a digital display. In addition, the display color changes from GREEN to RED when the pressure falls below the limit. If the valve moves to the open position, the control system immediately registers any pressure drop in the network and moves the valve back to the closed position. After the pressure on the compressor side has built up again and risen above the set value, the valve opens again. This process is repeated until the pressure previously entered into the control unit is reliably reached in the system. In this process, the network is filled gently and continuously, alternating between compressed air supply and compressed air compensation, without any components suffering damage. If the pressure on the mains side has risen above the lower hysteresis mark of the pressure switch, the valve opens permanently. The electronics allow various operating modes and settings, so that an individual setting can be made can be adapted to the conditions in the compressed air system.

APPLICATION EXAMPLE WITH SPECIAL CONTROL UNIT FOR VALVES WITH BLOW-ON SEAL

In transport systems for powdered media and granulates, shut-off valves are used whose ball valve, butterfly valve or gate valve is equipped with an inflatable seal. is equipped with an inflatable seal. Automation is also implemented in these process engineering applications with a pneumatic rotary actuator. In the CLOSED position, an inflatable seal is installed between the the housing of the shut-off device on the one hand or the ball, flap or slide valve on the other. optimum sealing effect is achieved. Until now, the valves for this function had to be equipped with extensive attachments such as solenoid valves, pressure switches, limit switches, etc. between the actuator and the controls. control system. This can very easily lead to damage and leaks. Here again the advantages of direct mounting without external attachments, as already mentioned at the beginning of this article. discussed at the beginning of this article.

The directly mounted and very compact barICS electro-pneumatic control system was designed for this application (Fig. 4). The control system coordinates the functional sequence of the OPEN and CLOSE movements of these special shut-off valves in conjunction with the sealing pressure. An additional advantage of using the bar-ICS is that this control unit only requires the OPEN/CLOSED signal and initializes and continues the entire sequence itself. This reduces the load on the plant control system and also ensures operational reliability during replacement and retrofitting. Via a digital pressure switch with freely selectable hysteresis, the seal pressure for inflating the seal or venting can be set separately. The pressure switch has two switching points, so that even during ongoing plant operation the sleeve of the valve can be checked for leaks. This control unit can be used for pneumatic rotary actuators as well as for linear actuators. Here, too, the plant operator can select the ideal combination for the production process in the automation of his valves. By means of freely selectable delay times, the control system can be optimally adapted to the respective application.

A color change on the pressure switch signals any seal defect that occurs during operation, so that the process can be directly influenced for inspection and maintenance. Various potential-free LED signal signals for monitoring the actuating times and the sealing pressure of the valve round off the extensive functions of the control system.

SIGNIFICANCE FOR USE IN OTHER PLANT PROCESSES

Based on the integrated air guidance between the pneumatic rotary actuator and the control unit

the various applicable product solutions from an end position feedback to the special control of complex plant processes have been presented here. Due to the reduction of sealing points and the conception as a closed system, these automation solutions stand out from the leakage-prone setups with external elements. External influences are much less likely to cause damage and failures. In addition, the coordinated and space-saving design results in a uniform equipment of the systems. The components of the bar-vacotrol system, consisting of control units and rotary actuators, can not only be easily assembled with each other as presented and in any combination. These modules can also be combined with conventional market drives and positioners. System components can be used to adapt to existing components in the plants. With this range of variation and the many possible combinations, the advantages for the plant operator lie in the simplified stock-keeping. Above all, there is the possibility to initiate the changeover process of the components without any problems and to carry it out in a smooth sequence. Variably adaptable properties of the control units from the bar-vacotrol system allow further individual developments to be made to existing