Centrifugal fans in steel industry are often exposed to rough and challenging conditions like vibrations, high temperatures and abrasive particles. While vibrations can mostly be avoided by balancing measures and temperature resistance achieved by the right choice of material and dimensioning of cooling discs, a resistance against abrasive particles still is a challenge for many centrifugal fans. So the dust load in the air as well as the size, the speed or the hardness of the particles determine the running time of a centrifugal fan in a steel plant. That was the main incentive for TLT Turbo to invest great efforts to considerably increase the running time of centrifugal fans in dust loaded conditions.

Already since approx. 1970, TLT-Turbo has performed particle jet wear experiments on various fan materials and coatings. For that, TLT-Turbo used a particle jet test stand, where a standardized test sand (with standardized grain size distribution) was blasted under a defined pressure / speed as well as special defined angles to surfaces of different fan materials and coatings. By exactly measuring the material loss after a defined amount of sand / time of blasting, TLT-Turbo determined erosion rates that correspond with the wear resistance of the investigated materials and coating. Figure 2 shows the old test stand.

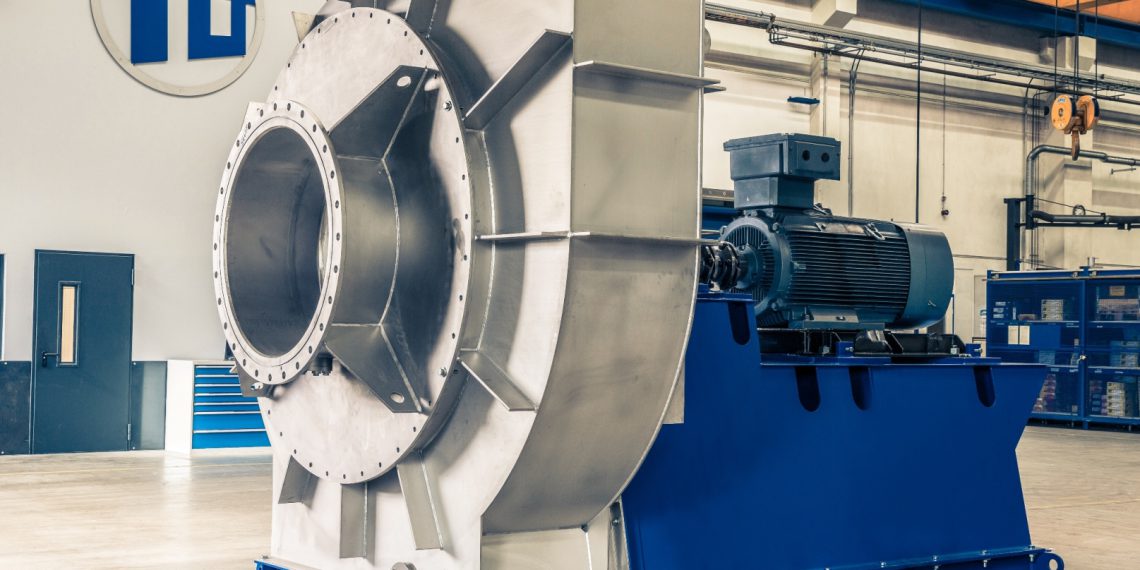

Research to increase running time

In 2014, a new materials laboratory was planned and has been successively extended since then. Next to high precision devices for determining an exact weight loss, coating thickness, microscopic examination of surfaces etc., the particle jet test stand was also upgraded. TLT-Turbo is now able to perform particle jet wear experiments with original customer dust and different speeds of the blasting particles. Additional to the findings of over 650 particle jet wear experiments, TLT-Turbo has been able to gain an even deeper understanding of the influence factors and mechanism of wear on centrifugal fans. Various approaches to master a combination of particle-induced wear and corrosion or wear during sintering can also be investigated on a scientific base in the new materials laboratory.

Next to the popular hardfacing solutions to prevent wear induced plant shutdowns, TLT-Turbo now is able to offer new and sophisticated thin layer coatings like H‑101 and H‑106. The choice of these thin layer coatings is based on particle jet wear experiments. To create the optimal solution for the customer in order to achieve the highest running time and a comparatively cheap price, TLT-Turbo investigated possibilities to combine hardfacing with thin layer coatings to hybrid coatings. To understand the virtue of a hybrid coating it is advisable to take a closer look at hardfacing and thin layer coatings first.

Hardfacing as popular wear protection

In different applications in steel industry, welded coatings on centrifugal fans have already been used since the 1980s. So in between, hardfacing is a well-established and standardized process (robot based automatic coating of impeller blades) and the costs per square meter are comparatively cheap. Another advantage is if wear induced local damages in the coating occur, the customer can repair it directly at the affected area in the impeller. By increasing the number of welded layers on the most exposed areas, the running time can be further increased. The only obstacle is the accessibility of the area in the impeller when it is integrated in the customer plant.

On the other side, hardfacing also has some disadvantages. If applied on fine grained steel, the incoming heat into the base material will impair the mechanical properties of the material. On a rotating part like an impeller, exposed to high centrifugal forces and vibrations, TLT-Turbo is not willing to risk insufficient mechanical properties. Instead, TLT-Turbo welds in hardfaced plates of uncritical base material that get attached to the impeller of fine grain steel by plug welding or screwing (if replaceable wear protection is required). The necessity of the uncritical base material contributes to the impeller weight. That disadvantage is further increased if the weight of the hardfacing itself is taken into account. The hardfacing has a thickness of 3–4mm that adds to the thickness of blades, partially on the center disc or even on the cover discs. Since centrifugal fans operate below their first resonance frequency and the resonance frequency gets determined by the stiffness of the shaft and the impeller weight, additional weight of the impellers requires a higher stiffness of the shaft. This gets implemented by a higher shaft diameter and, by that, higher weight. Also bigger bearings or heavier substructures might get necessary. So, additional weight on the impeller also causes considerable additional weight for the rest of the rotor, and consequently, additional costs.

Another disadvantage of centrifugal fans with hardfacing is the rough surface. This coarseness causes aerodynamic disturbances and has a negative impact on the efficiency of centrifugal fans in steel industry. Furthermore, the risk of caking (adhesion of dust particles on the surface) on blades or hardfaced areas rises. Figure 3 shows an example of a typical surface of a welded coating. Compared to sophisticated thin layer coatings a welded coating furthermore has a higher erosion rate. Figure 4 compares a typical erosion rate of a welded coating (green) with a typical thin layer coating (red) and TLT-Turbo’s H‑101.

The inferior erosion rate of a welded coating (especially at steep angles like 50–90°) only partly can be compensated by higher coating thickness. A typical welded coating thickness lies at 3–4mm, an HVOF coating often at 0.5mm.

Thin layer coatings as new alternative

For a couple of years now, thin layer coatings have been in special focus of TLT-Turbo’s Anti-Wear research. Experiments on TLT-Turbo’s particle jet test stand showed that especially High Velocity Oxygen Fuel (=HVOF) coatings proved to have superior erosion rates. This is a more costly but also high quality way of flame spraying. Especially in steel industry TLT-Turbo’s HVOF coatings like H‑101 are increasingly established. Table 1 shows an example of the extension of operating time by usage of different HVOF coatings for a centrifugal fan in a European steel plant.

Figure 4 and Table 1 have already shown H‑101’s superior erosion rate compared to typical welded coatings. However, further particle flow experiments with new chemical compositions revealed even better coatings. The most promising coating now is H‑106. Figure 5 shows a comparison between H‑106 and H‑101. In addition to the improved erosion rate of H‑106, also a higher thickness of up to 1mm is possible. But due to price pressure for centrifugal fans and a slightly reduced coating quality at high thicknesses, 1mm is only recommended on areas with extreme wear. A further advantage of the HVOF coatings is their smooth surface. In contrast to hardfacing, HVOF coatings have a hydraulic smooth surface for superior aerodynamic efficiency. Additionally, the lack of cracks and the low porosity of TLT-Turbo´s new HVOF coatings prevent local wear and chipping and protect the underlying base material from corrosive undermining. Figure 6 shows a close-up view of a typical HVOF surface.

However, HVOF coatings also have a few disadvantages. The main disadvantage is the price per square meter which is higher than a typical price of a common hardfacing. In CAPEX oriented markets that often prevents the choice of a HVOF coating. Another disadvantage of HVOF coatings is that their robustness (e.g. against major mechanical impacts like a blow of a hammer) can´t compete with hardfacing yet. That means it is advisable to handle a HVOF coating with more care than a welded coating. Else you risk a crack in the coating which is a starting point for further chipping and expose uncoated surfaces to abrasive dust. Figure 7 shows the result of a crack in the coating between a welded-in countersunk head screw and a wear blade.

Reasons for the crack might be a mechanical impact on the backside of the screw, a too strong tightening of the countersunk head screw or preloads caused during the welding-in of the screw into the plate. Also, a repair of a HVOF coating in the steel plant is expensive and difficult due to the installation situation.

Finally, a direct coating of an impeller is often not possible due to the accessibility of the areas to be coated. The individual geometry of the impeller and the position or the definition of the coating areas determines that possibility. To coat plates like radial blades or exposed areas on the center disc before welding is also possible. However, the welding of the separate parts together after coating impairs the coating quality in the intersection areas between the blades and the center disc.

Hybrid coating

Since both approaches – Hardfacing and HVOF – have their justification and are established in steel industry, TLT-Turbo searched for ways to combine their advantages. In order to add HVOF coatings like H‑106 on a typical welded coating some research was done. Finally, the efforts to merge these coatings together were successful. So TLT-Turbo is able to provide new wear protection possibilities for centrifugal fans in steel industry. Figure 8 shows a successful merge of both coatings. The most reasonable approach for TLT-Turbo now is to offer a cost efficient and robust hardfacing on the entire pressure side of blades and on the areas on center disc and cover disc that suffer most from wear. An evaluation of typical wear zones of centrifugal fans revealed that the wear is typically distributed unevenly on the blades of an impeller. Often, the leading edge and the outer area of a radial blade are the most exposed parts and have the highest material loss. On these comparatively small areas, therefore, an additional coating like H‑106 is applied. The thickness of that coating can also be adapted, depending on the wear pattern within the blade. With that measure, a typical running time without wear induced stops in the steel plant can be more than doubled compared to solely hardfaced impellers.

A further advantage of the solution is the comparatively cheap price for the blade with only slightly higher costs than a pure welded coating. This of course presumes that not the entire blade gets the hybrid coating, only those areas that are most prone for wear. Depending on the increase of operating time required by the steel plant, typical costs for a wear protected impeller are shown in Figure 9.

Also the customer will benefit from the robustness of the wear protection in the impeller. Mechanical impacts on the surface of the hybrid coating only would have a small effect on the HVOF surface. If local chipping occurs, it will be limited until the next crack of the underlying welded coating. If small local damages emerge, they won’t leave the base material exposed. In the previous example with the solely HVOF coated blades (Figure 7), an underlying hardfacing would have absorbed the impact and no crack would have occurred.

In contrast to a pure HVOV coating, local damage to a hybrid coating can also easily be repaired in a steel plant. Measures to repair a hybrid coating would only be taken if the hardfacing had already been damaged or vanished. All that needs to be done when local damages occur is to weld a new layer of hardfacing over the affected area. This can be done on site and even by the customer himself.

Furthermore, at least at the hybrid coating areas, the surface is smooth and aerodynamically beneficial. Small cracks get filled by the overlaying HVOF coating and only big cracks might stay open. Figure 10 showed 2 comparatively deep cracks partly filled with H‑101.

Also, the additional weight caused by HVOF is quite limited due to the local hybrid areas and their thickness of mostly only 500µm. So the total weight roughly equals that of common wear protected impellers. If however a pure HVOF coating will be replaced by a hybrid coating, e.g. at exchangeable wear blades, the thickness of the base material of the wear blade need to be reduced to compensate the additional weight by the welding.

Conclusion

A centrifugal fan in a steel plant is often exposed to abrasive dust which results in material loss and a shortage of running time for the fan. With TLT-Turbo´s new approach of hybrid coatings, even most challenging customer requirements can be met. Especially with the inclusion of H‑106, a drastically increased running time is now possible for the most wear exposed surfaces at the impeller.

A superior robustness, which is often demanded by a steel plant, is ensured as well as the customer’s option to repair damages independently and self-directedly. The costs for the new hybrid coating are also only slightly higher than those of a common hardfacing. To use the advantages of the new hybrid coating in your steel plant, TLT experts can be contacted at any time.